Pleated Filter Cartridges / Bags

Pleated Dust Collector Bags - The media used in these filter cartridges is manufactured using different technologies like spun bond, spun lace etc. These filters should only be used in applications containing free flowing dust.

Pleated bags provide higher efficiency than regular dust collector bags due to surface filtration. Also these bags provide 3 to 4 times larger area than the traditional pleated bags

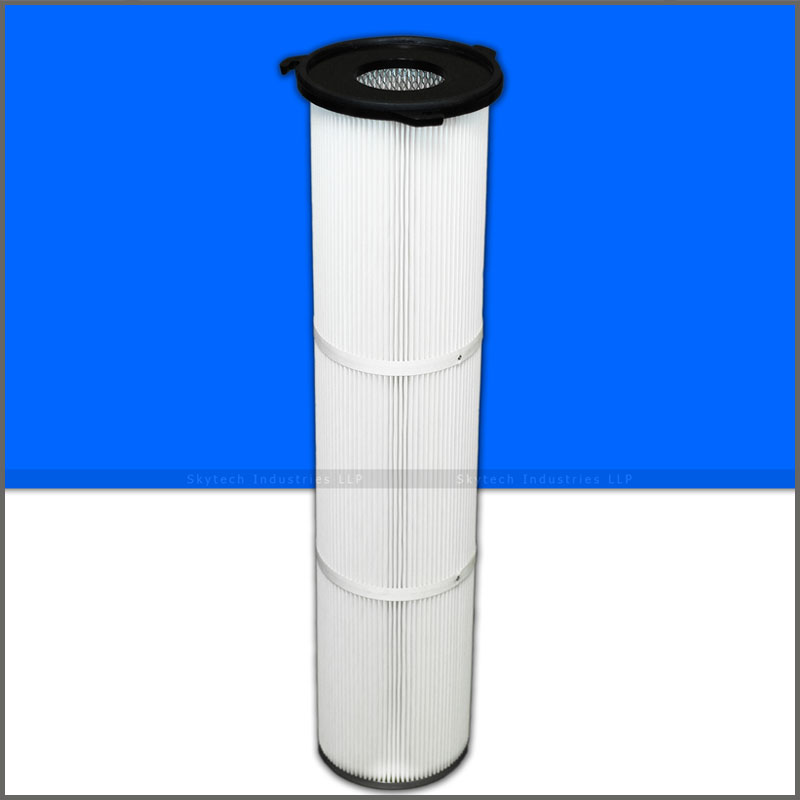

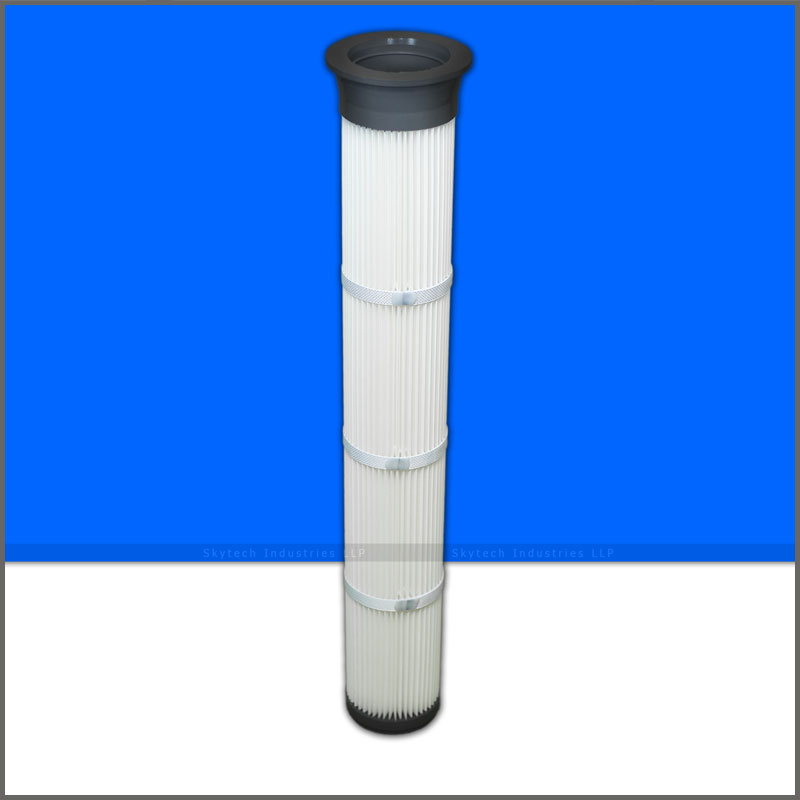

The four common designs which come in various sizes

- Lug Type

- Din Type

- Metallic Press Fit Type

- Poly-urethane (PU)

Filter Media Used

| Media | Temp Resistance | Acid | Alkalis | Hydrolysis | Oxydation |

|---|---|---|---|---|---|

| Polyester | 150 C | Good | Poor | Poor | Good |

| Aramid / Nomex / Conex. | 205 C | Poor | Excellent | Poor | Fair |

| Homopolymer Polyacrylonitrile. | 125 C | Good | Good | Good | Fair |

| PPS/ Ryton | 190 C | Excellent | Excellent | Excellent | Fair |

Area weight of filter media

- Ranges from 160 g/m2 to 400 g/m2 depending upon the quality of media.

Coating

- Anti Adhesive Coating

- Aluminium coating for antistatic application

- Fire retardant coating

- PTFE lamination for fine and agglomerating dust

Size & Filtration Area

Pleated filter cartridges/bags can be made in various sizes as per the requirement of the Filter/Bag House.

The filtration area can also be adjusted by increasing the number of pleats or increasing the pleat depth.